Un rider

En 2003, Pierre-Henry Servajean rêve de pouvoir rider en ville sans contrainte, sans avoir à choisir entre style et protection. BOLID’STER devient sa marque signature lors de sa création en 2015…

En savoir plus

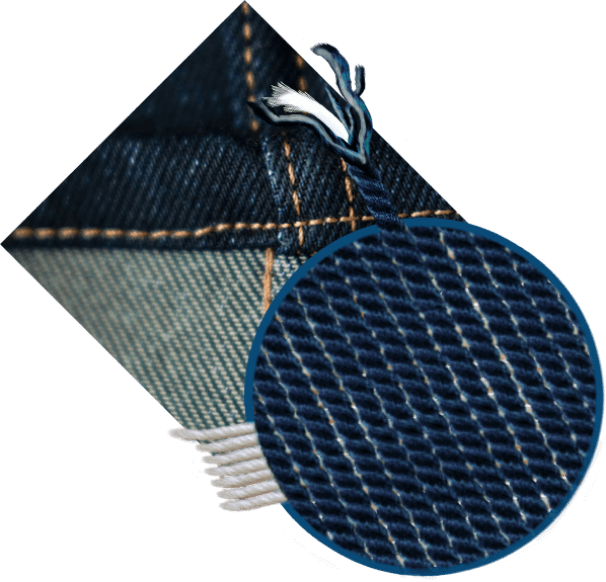

bolid’ster utilise uniquement LA PERFORMANCE DES TISSUS ARMALITH®,

La toile denim la plus solide au monde...

Ultra résistant à l’abrasion, à la déchirure, à la coupure, aux UV.

Technologie intégrée au coeur d’un authentique denim.

Stretch, léger, une seule couche de tissu, coton sur la peau.

En 2003, Pierre-Henry Servajean rêve de pouvoir rider en ville sans contrainte, sans avoir à choisir entre style et protection. BOLID’STER devient sa marque signature lors de sa création en 2015…

En savoir plusLe jean est un vêtement intemporel, pour tous et pour toutes, on le porte désormais sans distinction de classe, dans toutes les couches de la société. C’est un pantalon qui rassure, une seconde peau, à porter en été comme en hiver. Paradoxalement, le jean occupe une place à part dans nos dressings, en fait il y est totalement incontournable.

Dans l’univers textile, le jean est une pièce qui, étonnamment, a très sensiblement évolué depuis sa création. En vérité, l’évolution du jean a été marquée par de fortes mutations technologiques qui ont contribué à faire du denim le vêtement que l’on connaît aujourd’hui et que l’on porte finalement de la même manière.

BOLID’STER, avec la technologie de l’Armalith®, a ajouté sa pierre à l’édifice. Notre aventure est celle d’une nouvelle révolution textile.

À notre tour, nous nous sommes fait la promesse de créer la légende en ouvrant le tissu Armalith® en open source et en créant le jean le plus résistant du monde.

Achetez un jean au hasard, sans faire attention à ce que vous consommez. Mettez ce jean sur une table à côté d’un jean historique de 1880. Vous vous rendrez compte que c’est sensiblement le même vêtement : blanc et bleu à l’intérieur, bleu à l’extérieur, une usure dans le temps similaire, la même patine indigo, les coutures oranges, les rivets…. Bien sûr, on peut moderniser le jean et son process de fabrication à l’envi, reste que ce que l’on croise dans les rayons est encore très proche visuellement de ce que l’on pouvait faire il y a plus de 140 ans. Pourquoi une évolution si sensible ? Tout simplement parce que nous vivons dans un monde turbulent, qui change sans cesse. Quand il achète un jean, le consommateur ne recherche pas le changement. Il veut se rassurer. Le jean revêt un aspect nostalgique, c’est un marqueur sécurisant dans une époque de bouleversements profonds. Le grand symbole du jean c’est l’attachement à quelque chose de durable et de fiable.

1873 : c’est la date d’invention du “blue jeans” signé Jacob Davis et Levi Strauss. Gardons en tête ce jalon car c’est là que le jean historique tel que nous le défendons chez Bolid’Ster voit le jour. Bien sûr, on peut aussi vous raconter l’histoire du bleu de Gênes (blue jean vous l’aurez compris) inventé par les tisserands de Nîmes et qui donnera naissance au Serge de Nîmes. Mais ne nous égarons pas. C’est bien Jacob et Levi, les fameux, qui feront du jean le vêtement légendaire que l’on porte encore aujourd’hui.

En un brevet, le sort du jean est scellé. En pleine époque de ruée vers l’or, les mineurs ont besoin d’un vêtement solide. Jacob Davis met la main à la pâte, il utilise les toiles de Gène venues du magasin de gros Levis Strauss & co. L’association de Davis et Strauss est officialisée par le brevet qu’il faut alors déposer.

Mais au fond qu’est-ce qui différencie le jean d’un autre pantalon de travail ? Les mineurs se plaignent constamment que les poches de leurs pantalons se déchirent. Quant à Levi Strauss, il passe son temps à les recoudre. Il faut trouver une solution en rendant les jointures totalement fiables. Le rivet voit alors le jour. Un tout petit rivet qui pourrait paraître insignifiant et qui fera pourtant la différence. La première révolution du jean est en marche.

Mais voilà, le brevet arrive à son terme. D’autres fabricants peuvent désormais s’emparer du style Levi’s. La fin du succès Strauss et Davis ? Loin de là !

Tout le monde livre sa propre interprétation du jean riveté. Les modèles se multiplient, les styles évoluent. Tout n’est que diversité. Que fait Levi’s ? Il reste droit dans sa lignée ! L’aspect du jean original ne change pas et c’est en cela que l’entreprise reste encore aujourd’hui un géant dans l’univers textile. Levi’s a compris que la fiabilité et la permanence étaient des moteurs essentiels.

Seconde révolution du jean : le lycra et la révolutionnaire Fibre K inventée par la société Dupont. Et…celui qui réussit le premier à l'intégrer dans le jeans est Tejidos Royo, également fabricant de l’Armalith®. Vous nous voyez venir…

L’Armalith®, c’est incontestablement la troisième révolution que connaît actuellement le jean. Le pantalon du mineur devient un jean haute performance capable de protéger les motards de l’abrasion, à même d’accompagner les aventuriers et les amoureux de liberté sur tous les terrains.

En cela, le jean reste fidèle à ce qu’il a toujours représenté pendant des siècles : un symbole de liberté, un vecteur d’affranchissement. Voyez l’imaginaire qu’il véhicule, celui du soldat américain qui, au Japon, porte sa tenue militaire en semaine avant de revêtir son 501 le temps du week-end. Le GI américain et son jean incarnent l’espoir, le quartier libre. Autant de symboles que de nombreux pays vont pouvoir ensuite s’approprier.

Chez BOLID’STER, avec l’Armalith®, nous avons choisi de perpétuer ce digne symbole en offrant à chacun la possibilité de s’acheter un fragment de liberté, un morceau de peace of mind dans un monde affolant de bouleversements. Cette liberté, elle a d’abord été donnée aux motards, mais bien sûr elle est faite pour tous les aventuriers qui, avec le jean, cherchent à revêtir une armure synonyme d’évasion et d’indépendance.

Maintenant que la troisième révolution est en marche, que va-t-il se passer ? Chez BOLID’STER, nous allons d’abord nous charger de repenser le fonctionnement de l’industrie textile. On ne peut pas ignorer le futur qui se dessine sous nos yeux. L’eau est une ressource rare et pourtant indispensable à la production d’un pantalon en coton. Et puis, si l’on souhaite continuer à créer des vêtements avec des fibres naturelles, il nous faudra aussi toujours plus de terres arables. Nous devons anoblir l’industrie en recourant à d’autres matières premières. Nous devons aussi penser, plus que jamais, à celui qui fabrique le jean et pas seulement à celui qui le porte : le RIDE'STER IV chez BOLID’STER est par exemple conçu en phase avec les impératifs ergonomiques des ouvriers. C’est ça aussi, l’évolution du jean.

La seule frontière du jean est son tissu. Alors peut-être, dans dix ou quinze années, verrons-nous un nouveau jean profondément transformé grâce à l’introduction d’un squelette filaire.

Sur Instagram